Understanding buildings built with ashlar sandstone and granite facade

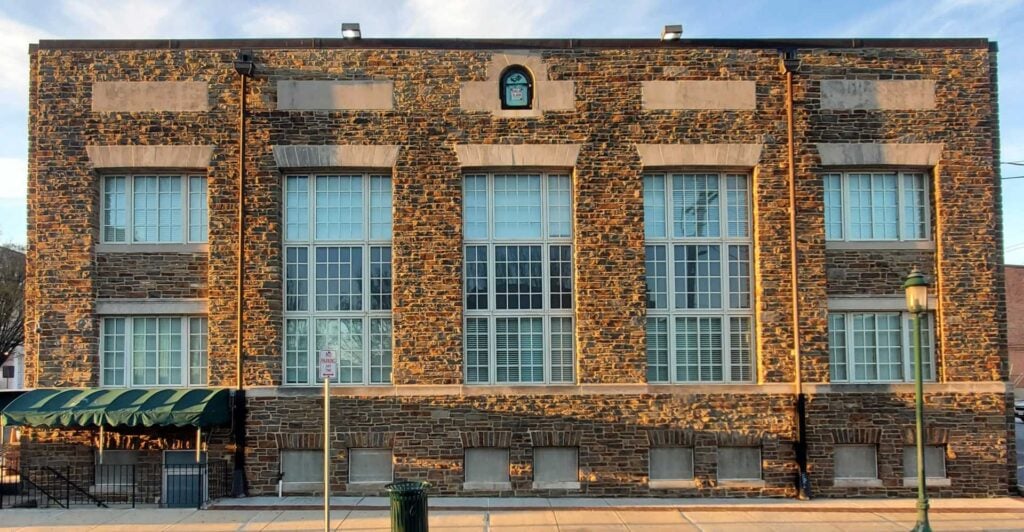

We recently had the opportunity to take a look at a beautiful hisroric masonry building. Unlike much of the typical brick buildings that we see so often in the downtown and historic areas of Washington DC, this particular building happens to be entirely built with a stone exterior facade. Much of the stone is built with granite, but there are sandstone accents throughout the exterior.

Much of the architectural fabric of our city is built from historic brickwork. The brick and mortar of the early 20th century and even late 19th century is very unique and not common in much of the rest of the world. Brick has been used throughout the world for thousands of years, but there are elements of that brick and mortar which are unique to both Washington DC and also unique to that particular era and time period as the technology changed. The technological drivers in manufacturing and material science changed the way cities were built.

How Brick Masonry Has Changed

By comparison though, although there have been technical changes in the characteristics of stone mortar, much of stone masonry has remained the same while brick masonry has changed significantly over the same time period.

The picture below shows the exterior South facing facade of a split face ashlar granite stone building. The facade is basically comprised of 6 massive columns of stone with a line of structural headers that run across connecting these large openings at a continuous wall Hñheader above.

Granite stone and brick masonry are very similar in terms of methodologies of construction. Brick though because it is formed and fired into a relatively uniform shape is more consistent and easier to build structures which benefit from the efficiencies in uniformity and modularity. By contrast though, on the other hand grantle stone is far superior in terms of compressive strength. Granite stone can be over 10 times the compressive strength of historic common brick and mortar. Without much fault, it sounds clearly better, stone is stronger and therefore stone buildings are better and yes, granite stone specifically has a much higher compressive strength, stone buildings are not just simply and necessarily better than brick buildings. Brick buildings can still last for hundreds of years and also have sufficient resistance to the spread of fire.

In any type of masonry structure, but particularly as seen at this structure with very tall columns, in the exterior wall layout, that run between window openings which make up the majority of the South facing facade, it’s extremely important to build the corners plumb and true. Particular detail has been applied, not just to the installation of the wall at each of the individual corner locations, but also in selecting and culling the stone for constructing the corners. The work in the field, the area between the openings and the corners, is also important but it’s comparatively simple and fast to build the field portions of the courses once the wall corners have been properly established.

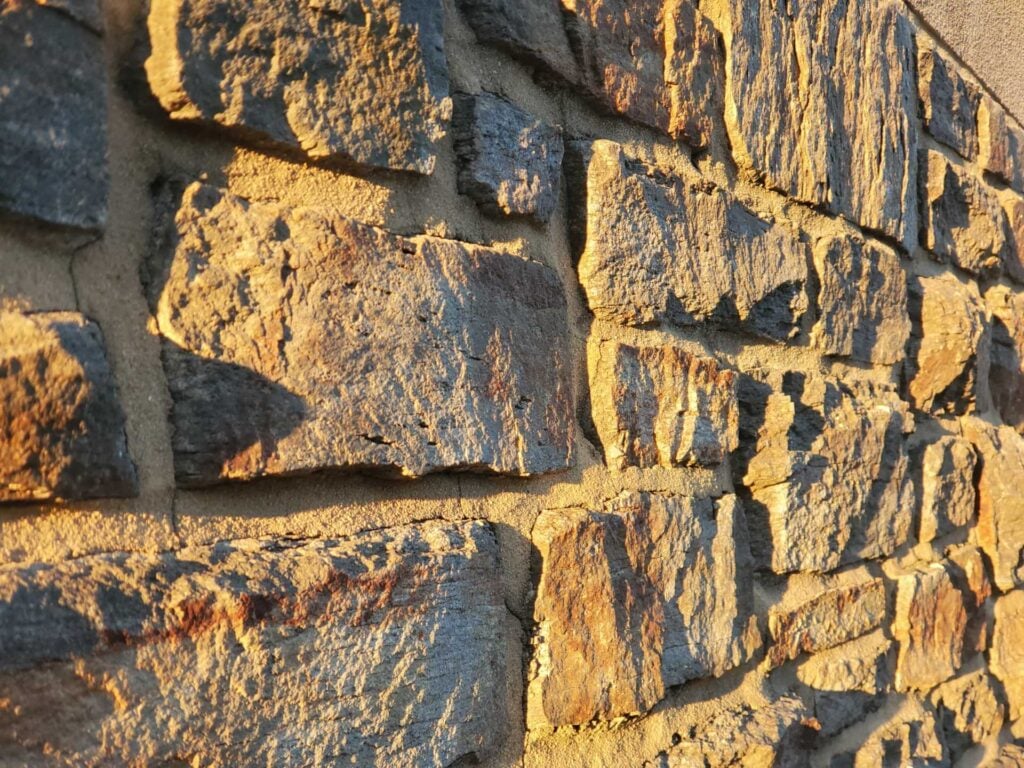

A closer look at a corner, shows how the interlocking stones alternate between larger and smaller stones at each course of the masonry. This interlocking nature is referred to as the bond, because the strength of the wall assembly is largely derived from that context and relationship between the stones. The same bond, context, and relationship is inherent in brickwork and brick wall assemblies as well.

Repointing Work On Hold Mortar

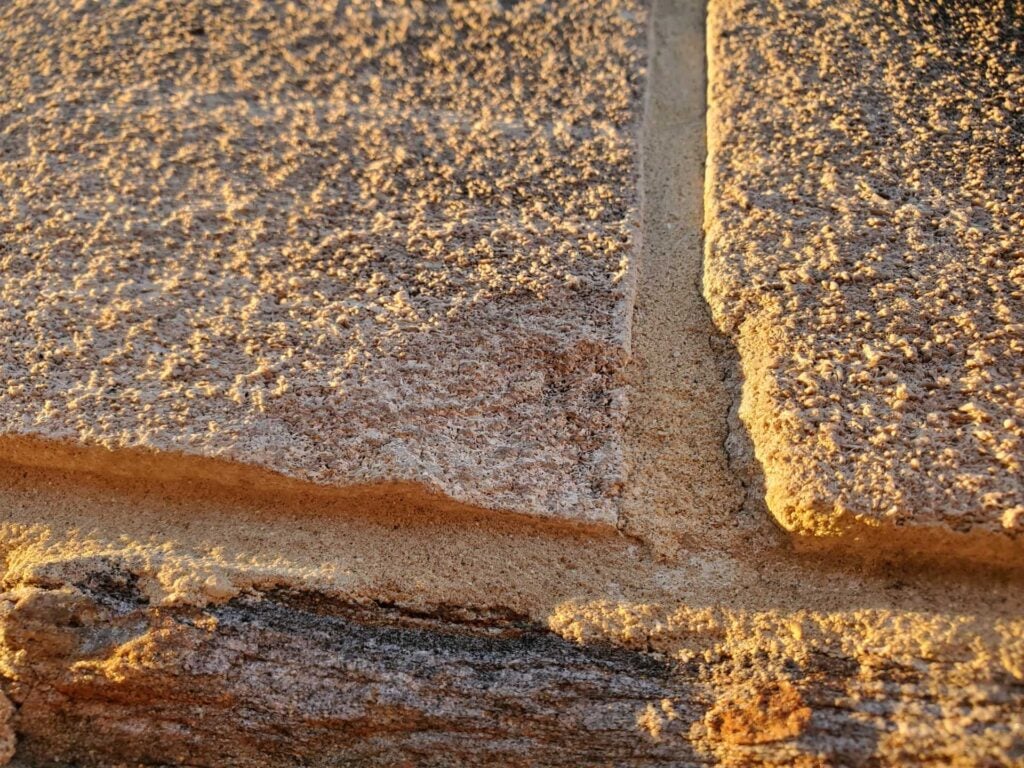

In this photo, you can also see that some repointing work, or tuckpointing, of the old motor has been completed to repair that mortar where windows were installed in the middle of the lifespan of the building. Tuckpointing or repointing is the process of removal of old mortar at the surface of a wall assembly amd replacement of that mortar to a depth over about 1″ from the outer face. This process is extremely tedious and difficult work but it is required as buildings age, to maintain and preserve the building. Historic masonry buildings have extremely long potential lifespans if properly maintained, tuck pointed or repointed and restored throughout the life cycle of the building.

Common brick joints, and historic brick masonry as seen throughout much of Washington DC, are relatively large mortar joints. The pressed brick at the typical front facades of some of the classic rowhomes in Washington DC have much finer joints. We refer to those mortar joints as butter joints. The common brick though, has larger joints that can be up to or even in some cases over 3/4 of an inch in height or thickness.

That’s relatively thick for a brick joint. Here in the case of stone work though some of the mortar joints are actually even a bit larger than 3/4 of an inch because there is much greater variation in the size and shape of these stones. Brick work though by comparison should have much less variation overall and the large mortar joints that are often found in common brickwork are also, not just due to the variation in the brickwork, but also a result of the historic cost difference between mortar and brick.

Looking At Historic Stonework With Modern Touches

The next 2 pictures below show a view of the stone work at an angle to highlight the difference and variation between the stones, particularly at the projecting vertical face. The bed and head joints of the stonework, in some cases are cut more uniformly.

The next picture below shows a very similar angle, but the pronounced shadow highlights the difference and deviation, and overall variation between the split face of much of the stones.

The next picture below shows the wall from a similar distance, but at a direct angle, almost 90゚ from the wall itself. In this particular picture, you can get a better sense of the ashlar nature of the stonework. Although it is an ashlar masonry, meaning that it has been cut and formed to lay flat or somewhat rectilinear, as it is set into a masonry assembly, in the form of the wall, it’s not consistent or uniform. In fact some stones are much smaller than others, but through piecing it together, a little bit like a puzzle, the wall is assembled. Rubble masonry by comparison is much less stable but does not require the massive effort to cut and shape each stone.

Windows and Roofing Case Study

In the next picture below, you can see the Jack arch of one of the window headers.

The next picture shows a different, but very similar header from an angle below looking up. At this angle you can see the multiple stones that have been built together in alternating layout to create the structural header.

Security screens have been installed at the window openings at the lower level to prevent theft and break in to the building from the outside. These particular security panels are connected to a ½ inch x ½ inch steel inserts which has been embedded into the stone work.

The sandstone sills at all of the window openings at the building have been refurbished and restored in recent years. You can see the distinct mortor joint at the area below the sandstone sill.

The original mortar of this building was likely similar, with a yellow color sand but the original motor was likely much higher in lime composition. This current mortar is a blend of modern mortar with historic characteristics. And although lime is likely present in the motor, the ratio or proportion of lime to other materials is likely a lower percentage.

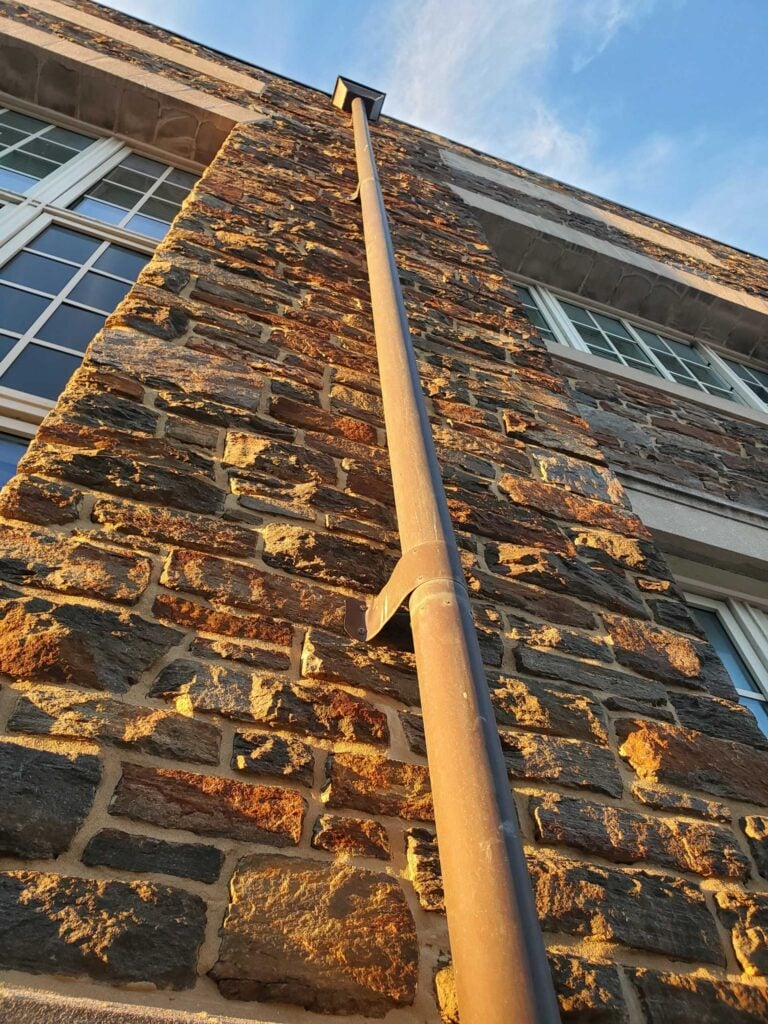

Rainwater and precipitation, at the roof of the building, are conveyed away from the roof through a rooftop scupper which goes from the flst or low slope roof, through the exterior facade of the building, to a conductor head or downspout leader head and from there runs to a rain leader underground to the public stormwater system.

A building facade works in several different ways to encapsulate and protect the interior of the building from the exterior elements for many generations and even centurias if properly built and cared for throughout its life.

Maintaining Historic Buildings In Washington, DC

To properly maintain, repair, and care for these historic buildings, a knowledge, interest and understanding of historic building principles is required. Here in Washington DC, historic masonry buildings are extremely expensive and the amount of financial loss caused by improper repointing and low quality construction is staggering. However, in addition to the direct financial value of the property, there is also a cultural loss when historic buildings are damaged. By comparison, consider neighboring poor cities, when historic buildings are damaged, it’s not just the loss of value to the property owner, there’s also a loss to all inhabitants and visitors of a city, present and future, who care about architecture, history, and culture.

We encourage all of our clients, and all readers of this article and to our blog in general, to prioritize the historic built environment of Washington DC and neighborhoods such as Capitol Hill, Dupont Circle, and Georgetown and become educated on on the difference between proper historic preservation versus improper work which leads to significant damage to the historic fabric of a building.

From a conservation and preservation perspective, several approaches can be taken to improve conditions related to deteriorated historic brick masonry. Primarily, lime mortar brick joints and low temperature fired soft red clay bricks should be inspected and checked on a routine maintenance schedule, either seasonally or at least annually. If brick masonry is kept in good condition, the life of embedded wood elements can be significantly extended. Hire a professional contractor which specializes, understands and appreciates historic construction elements and buildings.

In this article we talked about the terminology and concepts of historic masonry restoration, follow the links below for more related information from the IDS website:

- Binders in mortars and concrete

- Brick burns

- Butter joint

- Capillary action

- Cantilever

- Cementitious siding

- Cheek wall, masonry — Draft

- Chemical testing

- Code, building — Draft

- Cold joint

- Cold weather masonry work — Draft

- Damp proof course

- Downspout

- Electrical distribution panel — Draft

- Fenestration

- Ferrous metals

- Great Chicago Fire

- Green bricks

- Gutter, roof

- Lime mortar

- Lintel

- Load path

- Oriel window

- Oxidation

- Parapet coping

- Plug, clay

- Pressed bricks

- Raking, of mortar joints

- Raggle, aka reglet

- Rectilinear

- Roman bricks

- Roman arches

- Roof eave

- Roof termination

- Row buildings and row homes

-

- Rubbed bricks

- Rubble stone masonry

- Sand, Builder’s

- Sedimentary rock

- Scratch coat

- Sprung arch

-

- Squint bricks,

- Strike, or striking of mortar

- Tapestry bricks

- Tooth-in, interlocking masonry connections

- Vitreous

- Water diversion systems

- Zipper-joint

These concepts are part of the fundamentals of historic masonry restoration, tuckpointing, and brick repair.

The links in the list above will take you to other articles with more information on defects, failures, preservation and repair of historic masonry. You can learn a lot more on our blog. Feel free to check it out. If you have questions about the historic masonry of your building in Washington DC, contact us or fill out the webform below and drop us a line. We will be in touch if we can help.